By Roger Russell

These pages are copyrighted.

No portion of this site may be reproduced in whole or in part

without written permission of the author.

|

Ceramic Microphones |

The Research Laboratory |

![]()

Sonotone began making consumer microphones in the early 1960's. These are the ceramic type using the same kind of barium titinate elements that were used in their phonograph cartridges. This includeds a number of variations made for special applications like tape recorders, language labs and citizen band radios. The basic cartridge design remained the same.

The Ceramic microphones are excellent performers,

particularly at low frequencies, and are inexpensive. A joint patent number

3,004,177 was issued to Ilyitch J Sobel and Edward Lessing in October of 1961

for the concept of the CM-10A microphone cartridge. Some of the construction

was very similar to the ceramic phonograph cartridges. This cross section

picture is from the patent.

The Ceramic microphones are excellent performers,

particularly at low frequencies, and are inexpensive. A joint patent number

3,004,177 was issued to Ilyitch J Sobel and Edward Lessing in October of 1961

for the concept of the CM-10A microphone cartridge. Some of the construction

was very similar to the ceramic phonograph cartridges. This cross section

picture is from the patent.

By 1967, a line of dynamic microphones was introduced. With the advent of transistorized consumer products, low impedance microphones were in more demand. The input impedance required for ceramic microphones was generally high, preferably one megohm or more. Although a low impedance ceramic element was introduced into the line, the low frequency response still suffered a loss. The only solution was the inherent lower impedance available with dynamic microphones.

![]()

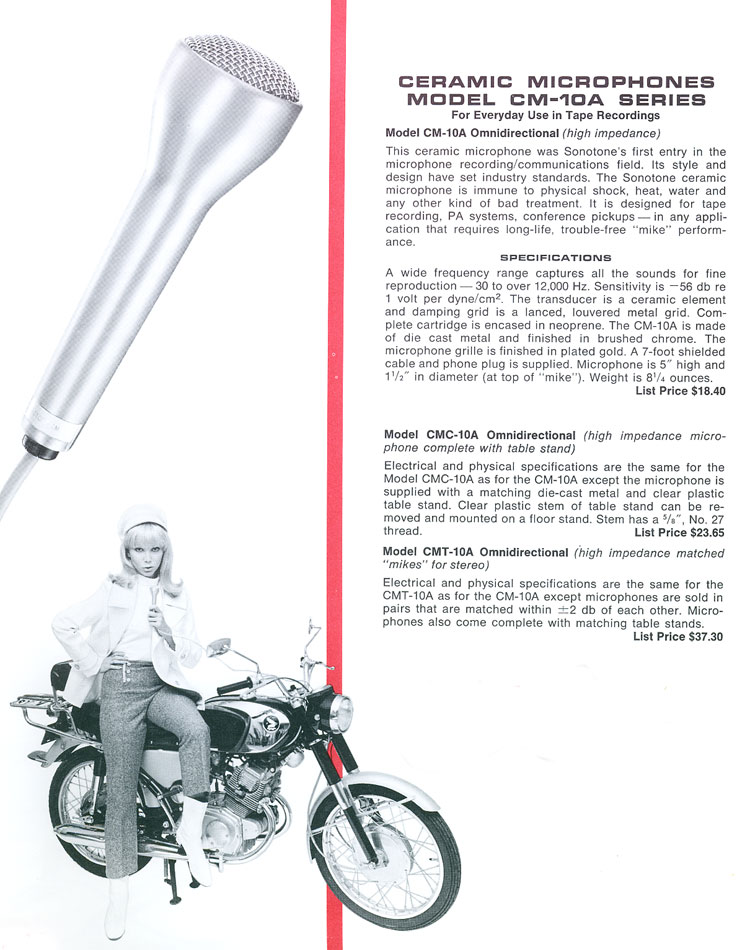

One of the most popular ceramic microphones was the

ice cream cone shaped CM10A. It was sold by Sonotone but was also sold in large

OEM (original equipment manufacturer) quantities to companies like General

Electric and Voice of Music (VM).

They were featured in VM advertising for the model 722 and 754 tape recorders.

VM also bought microphones having different construction from several other

companies including Ronette. CBS marketed a ceramic microphone kit made by Ronette in the early 1960s.

One of the most popular ceramic microphones was the

ice cream cone shaped CM10A. It was sold by Sonotone but was also sold in large

OEM (original equipment manufacturer) quantities to companies like General

Electric and Voice of Music (VM).

They were featured in VM advertising for the model 722 and 754 tape recorders.

VM also bought microphones having different construction from several other

companies including Ronette. CBS marketed a ceramic microphone kit made by Ronette in the early 1960s.

Sonotone microphones could be purchased individually or as a matched pair. In truth, all of the microphones had sensitivity within 1 dB but were guaranteed if you bought the matched pair. It measures 5" high by 1-1/2" in diameter at the top. Weight is 8-1/4 ounces. Response is from 30 Hz to over 12 kHz. Sensitivity is -56 dB re 1 volt per microbar. A load impedance of one meg-ohm or higher is required for good low frequency response. This microphone is extremely rugged and was typically demonstrated at the high fidelity shows hanging in water in a fish tank and then used to hammer nails into a board. It survived unaffected except for a few scratches from the nails.

|

|

|

|

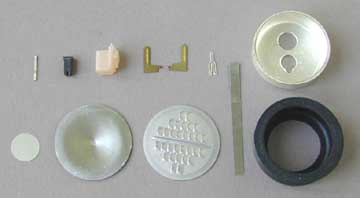

Parts identified from top left to bottom right |

|

|

(1) Ceramic element |

(7) Cup |

The heart of the microphone is the bar shaped lead-zirconium titanate element (1). It measures 0.021" by 0.040" and 0.430" long. It is mounted in a high durometer rubber pad (2) and placed in a small rigid plastic housing (3). Positive and negative contacts (4) slide into place between the rubber and the ceramic element, one on the top and one on the bottom. This assembly is glued inside the steel cup (7) and located in a key slot in the cup. The cup is silver plated. The leads go through to the rear of the cup. A fiberglass rod (5) is attached to the ceramic element. The diaphragm (9) is made of shaped 0.7 mil aluminum. This is formed using a hardened steel die and a piece of high durometer rubber that presses a disc of aluminum into the correct shape. The edge of the diaphragm is cemented to the rim of the cup using Vulcaloc adhesive. The rod protrudes through a hole in the center of the diaphragm. The rod is attached to the diaphragm with a high temperature wax. We used a controlled temperature soldering iron with a specially shaped tip to do this. The round hole in the bottom of the cup is covered with a nylon cloth (8) that provides an acoustic resistance to the rear chamber in the microphone handle. A louvered aluminum acoustic filter (10) is placed in front of the diaphragm to control the mid-range response. A star is stamped into the front of the aluminum to identify that it is used in the CM10A. A ground strap (6) is connected to one of the cartridge assembly contacts. A molded rubber enclosure (11) is placed around the cartridge.

|

|

|

|

|

|

|

(12) Handle |

(14) Heyco strain relief |

The single conductor shielded microphone cable is brought through the handle (12) and inserted through a rubber sealing plug (13). The handle is made of die cast zinc with a brushed chrome plate finish. The handles were made in Japan. Contacts soldered to the ends of the cable slide onto the two pins from the cartridge, the shielded portion of the cable going to the contact with the ground strap. A small amount of silicone lubricant is used in the cable to reduce friction when the microphone cable, plug and cartridge are pulled into the handle. This forms a very tight seal between the microphone cartridge and the outside world. The seal was so good that when the microphones were shipped by air in a non-pressurized shipping area, the diaphragms blew out. It was necessary to relieve the pressure with a very fine hole in the diaphragm made by a fine wire. The ground strap then contacts the handle. The Heyco strain relief (14) is placed around the cable near the end of the handle. A special tool is used to crimp it to the cable and insert it into the handle. A decorative gold plated wire grille (15) is attached to the front. The wire grille is glued in place using Eastman 910 adhesive.

Lower impedance ceramic elements were new in 1962. The normal ceramic element was a bimorph, with the two outside surfaces polarized positive. This element was connected in series when in use and had a capacity of 440pf. The low impedance element, supplied by Gulton Industries, was assembled and polarized for parallel connection. The capacity of these elements was 1750pf. A low impedance element means the same response can be obtained, but with the microphone working into a lower impedance load. This was valuable when used with transistor equipment. It was also less affected by cable capacity.

The effect of cable capacity is different with a ceramic element. Normally, the capacity in a shielded cable will alter the high frequency response of a high impedance dynamic microphone or magnetic cartridge. The ceramic element, electrically, is a voltage source in series with a capacitor. The cable capacity forms a voltage divider with the ceramic element and reduces the overall output uniformly with frequency. Special low capacity shielded foam cable was used for the ceramic microphones and cartridges to reduce this loss in output.

Optional microphone stands were also available. The handle can be inserted into a sleeve holder which is attached to a standard coupling having an internal thread. The clear Lucite sleeve makes a very attractive display. The base is relatively heavy and is made of a zinc alloy. A ring of cork or felt is attached to the bottom of the base to prevent scratching tables, etc. The holder can be rotated from a horizontal to a vertical position.

The slot allows room for the microphone cord to exit. The holder portion can be unscrewed from the base and can be attached to any microphone equipment that has a standard thread. Unfortunately, we found in use that the microphone handle could accidentally be forced too far into the tapered sleeve resulting in craze marks in the clear Lucite and some of them actually cracked in several places. Later sleeves were made of white Implex and that solved the problem.

![]()

Dynamic microphones are entirely different. The cartridges are like small speakers having a magnet structure and a circular coil of many turns suspended in a magnetic gap. The coil is attached to a diaphragm, usually dome shaped. When sound strikes the diaphragm, it moves the coil in the magnetic gap following the variations in the sound pressure. This in turn produces a corresponding electrical current in the coil that can then connected to an amplifier. The magnets are made of alnico.

The DM-10 is at the top of the picture

The DM-10 is at the top of the picture

The CDM 80 is the microphone in the center of the picture. This has a super-cardioid response pattern that has a front-to back sensitivity rejection of 20 dB. This was available in 200 or 50k ohms and normally has an on-off switch.

The DM 70 series is at the bottom of the picture. This has a slightly lower output but covers a wider frequency range and is omnidirectional. These were available with impedances of 50K, 10Kand 200 ohms. The 200 ohm version was also available with an on-off switch.

I designed three basic models of dynamic microphones. They were available in matched pairs, although production normally ran within one dB. The handles all fit into the same sleeve holders, clear or white, for use with stands. A Heco strain relief was used at the bottom of the handles in early models but was changed later to a molded rubber strain relief instead.

Sonotone DM-10 Microphone

The DM-10 microphone is a high output omnidirectional model. They were available with impedances of 50K, 10K and 200 ohms. The 200 ohm version was also available with an on-off switch. It has the same cast zinc handle as the CM 10 ceramic microphones.

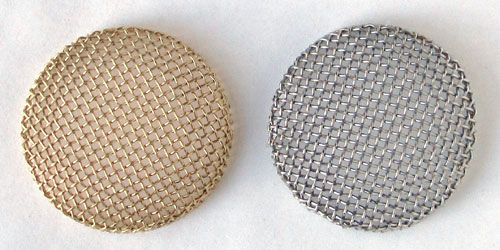

All of

the ceramic models have a gold plated wire dress grille. To easily distinguish

the different types, all of the dynamic models have a chrome plated dress

grille.

|

|

|

The appearance through the grille is also different. The ceramic mics have an aluminum louvered grille in front of the diaphragm and is held in place with the rubber cup. The dynamic cartridge originally had a 1/8 gray urethane foam disc used a windscreen. However, the foam deteriorated and crumbled over the years exposing the DM-10 dynamic cartridge. The mylar diaphragm can be seen as well as the aluminum phasing dome held in place with the three supports. The cartridge is held in place with the rubber cup.

Here is a CDM80 microphone in the white Implex sleeve.

The CDM80 was one of my pet projects, a directional dynamic cardioid design. In

omnidirectional design, the rear of the cartridge is essentially sealed to the

outside world. Cardioid response is achieved by the addition of sound ports at

the rear of the cartridge. Sound waves originating in front of the microphone

arrive at the diaphragm first and are delayed by the path length and an

acoustic resistance placed across the ports before reaching the rear of the

diaphragm. There is diaphragm motion and output. However, sound waves

originating from the side and rear of the microphone are delayed through the

ports by the same amount of time it takes them to reach the front of the

microphone. The resulting pressure at the front and rear of the diaphragm is

the same and there is no net diaphragm motion, and no output.

Here is a CDM80 microphone in the white Implex sleeve.

The CDM80 was one of my pet projects, a directional dynamic cardioid design. In

omnidirectional design, the rear of the cartridge is essentially sealed to the

outside world. Cardioid response is achieved by the addition of sound ports at

the rear of the cartridge. Sound waves originating in front of the microphone

arrive at the diaphragm first and are delayed by the path length and an

acoustic resistance placed across the ports before reaching the rear of the

diaphragm. There is diaphragm motion and output. However, sound waves

originating from the side and rear of the microphone are delayed through the

ports by the same amount of time it takes them to reach the front of the

microphone. The resulting pressure at the front and rear of the diaphragm is

the same and there is no net diaphragm motion, and no output.

The original cartridge from Primo has side ports but

didn't give adequate front to back rejection. I created fluted side ports in

the handle to provide a rear entrance to the Primo cartridge and diaphragm.

Addition of an acoustic resistance across the handle ports even more

effectively delays the sound coming to the rear of the microphone diaphragm.

Finely woven black nylon cloth attached to thin perforated plastic was used as

the acoustic resistance.

The original cartridge from Primo has side ports but

didn't give adequate front to back rejection. I created fluted side ports in

the handle to provide a rear entrance to the Primo cartridge and diaphragm.

Addition of an acoustic resistance across the handle ports even more

effectively delays the sound coming to the rear of the microphone diaphragm.

Finely woven black nylon cloth attached to thin perforated plastic was used as

the acoustic resistance.

Besides styling, the flutes also served another more subtle purpose. If the microphone were inadvertently held near the front, the hand might cover the ports. The deep flutes insured there would still be a sufficient opening to maintain good front-to-back rejection. I noticed that my idea was adopted the following year by Electro-Voice.

The AR-1 speaker system that had been used for many years was not accurate for directional microphone measurement. The woofer and tweeter were located at different places on the cabinet front. The directional response of the CDM80 microphone required a new sound source that has a coaxially mounted woofer and tweeter. I used a Tannoy Gold Monitor loudspeaker in a large sealed cabinet.

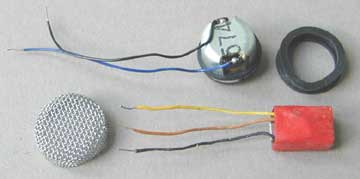

The dynamic microphone cartridges were not made by

Sonotone. They were purchased from Primo, in Japan. The cartridges were made

with impedances of 35, 43 or 200 ohms. The picture at the left shows a DM 70

cartridge. It measures about ½" in diameter. The cartridge fits inside the

rubber grommet which then fits in the handle.

The dynamic microphone cartridges were not made by

Sonotone. They were purchased from Primo, in Japan. The cartridges were made

with impedances of 35, 43 or 200 ohms. The picture at the left shows a DM 70

cartridge. It measures about ½" in diameter. The cartridge fits inside the

rubber grommet which then fits in the handle.

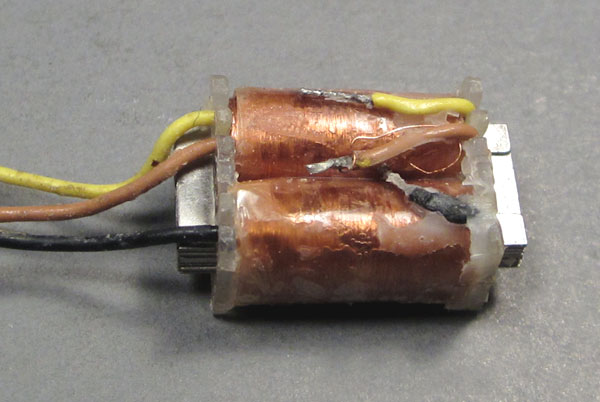

The transformer has red insulating tape around it. Connections are made to the cartridge, transformer and cable. The assembly is then pulled inside the handle with the cable. The wire mesh grille is cemented in place.

The dynamic microphones all had a 1/8 reticulated urethane foam wind-screen under the grille.

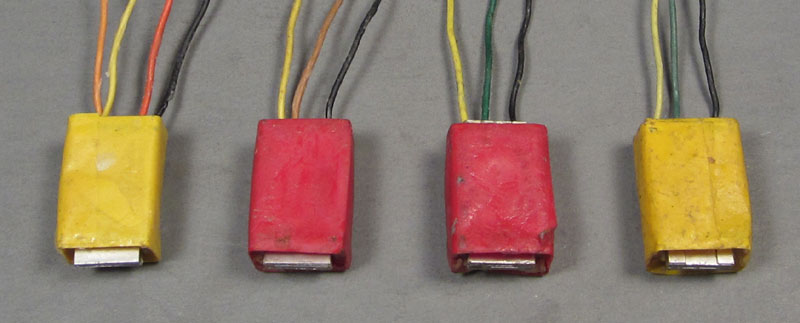

Four different microphone transformers are used in the DM10, DM70 and CDM80 series of microphones. They convert the low impedance of the cartridge to the higher impedance depending on the intended use. The lower impedance cartridges are connected to a transformer and then to the microphone cable. The 200 ohm cartridges for a balanced line connection go directly to the microphone cable and do not use a transformer. A typical transformer measures 3/4 wide, 1/2 deep, 5/16 thick and weighs 5-1/2 grams (0.2 ounces).

The text corresponds to the above pictures

|

Yellow tape |

Red tape |

Red tape |

Yellow tape |

|

35 to 50k ohms |

200 to 10k ohms |

43 to 10k ohms |

43 to 50k ohms |

|

orange

35 ohms |

Brown

200 ohms |

Green

43 ohms |

Green

43 ohms |

The tiny transformers have dual coil windings on a plastic bobbin. Laminations are inserted in alternating directions. The fine coil wires are soldered to the colored take-out wires. Several layers of tape are wrapped around the subassembly. The final transformer is dipped in wax to hold the assembly in place.

A complete list of microphones that were available is further down on this page.

Sonotone had the opportunity to bid on a contract for underwater microphones (hydrophones) for the navy. They were to be used for acoustic detection of submarines. A series of sonobuoys, each using a hydrophone, could be dropped in a row by air. The hydrophones automatically lowered to a depth of 60 feet. The acoustic information was transmitted from the sonobuoys to the aircraft. With the use of sophisticated detection equipment, the submarine position could be located. I was the design and test engineer.

The heart of the hydrophone is a 1" ceramic disc held on one side, at the rim, by a rigid plastic shelf that was mounted in an aluminum cup. The other side has a thick aluminum diaphragm coupled to the center of the ceramic disc with a controlled durometer rubber pad. One end of the 60 foot shielded cable is soldered directly to either side of the ceramic disc. A special low durometer strain relief also forms a high pressure seal to the aluminum cup assembly. The assembly is mounted in a rubber housing about 2" in Diameter and 1/2" thick, having a formed strain relief where the cable entered.

In the air tests, I measured response extended flat to below 20Hz and up to1kHz, rising to a peak at about 6kHz. Test results for acceptance showed the expected extra loading by water on the diaphragm produced essentially flat response to about 2.5kHz. I also made pressure tests in water in a special test tank to check for leakage. Although the hydrophone passed all the mil-spec tests, including pressure testing, we did not get the contract.

![]()

Headset-Microphones

To expand the line of products for use in language

labs, a boom microphone was designed to be attached to a Sonotone headset. The headsets

were made by Clevite and were available in crystal, ceramic and low impedance

ceramic. The earphone cushions were either urethane foam on a cloth pad or

extra-soft "donut" cushions. They were attached to each earphone with

Velcro for easy replacement. Each earphone diaphragm was protected by a disc of

sintered brass granules. The disc also acted as an acoustic resistance to

smooth out the headphone response.

A CM30 cartridge was used for the ceramic microphone version. It was shallower than the CM-10 cartridge. The cartridge was mounted in a plastic boom cup. The rear of the boom cup had many small holes in the rear to provide noise canceling response.

Noise canceling occurs when plane acoustic waves from distant sources arrive at the front and rear of the diaphragm at the same time. There is no resulting diaphragm motion, and consequently no output. The resulting low frequency sensitivity is greatly reduced. Spherical waves from a close source arrive at the front of the diaphragm but are delayed by the path length to the rear. There is resulting diaphragm motion, and low frequency response is restored. This is known as the proximity effect, and works to great advantage for close talking.

A balanced reed magnetic microphone cartridge was used for the low impedance version. This is very similar to the microphones used in some of the Sonotone hearing aids. It is small, yet has high output, and works very well as a noise canceling mike.

The other end of the curved stainless steel microphone boom is attached to a plastic clamp that is tensioned with two Belville washers. A large knurled knob can be used to tighten the clamp after the microphone is at the desired position. The assembly can be purchased already installed on the headset, or can be added later.

Another speaker is needed to simulate close talking for testing the close talking microphones. A 3" KLH wide range speaker is used. The driver is only a few inches in diameter and covers the required frequency range. The microphone is placed 1" from the speaker.

![]()

Microphone and hearing aid research shared the same laboratory area. This is where I worked most of the time. I learned a few things about hearing aids as a result. Marty Molloy headed the hearing aid research and Bill Knauert headed the microphones. They both reported to Harry Pearson who was Director of Research. I will always remember the articulation tests that the engineers would recite while wearing an experimental model hearing aid. There were favorite phrases like "Joe took father's shoe bench out" or "She was waiting on my lawn"

Three walk-in test booths were used for making response measurements of consumer and hearing aid microphones. The booths were approximately 8 feet deep, six feet wide and 7 feet high. They were lined with acoustic material. A heavy freezer locker door provided good acoustic isolation. The booths rested on heavy rubber isolation pads. An AR-1 loudspeaker was used for the sound source and was positioned in one corner about 3 feet from the floor. A calibrated point in space was located with a mark on a permanently located string in front of the tweeter.

A rack of test equipment was provided just outside each booth. A General Radio 1304B Oscillator was used to drive a McIntosh MC30 amplifier which was connected to the AR-1. The oscillator was chain driven by a Sound Apparatus chart recorder and response curves were automatically plotted. The microphone was connected to a cathode follower located in the booth. The cathode follower provided high input impedance and low output impedance. Different load resistors could be connected to the microphone in the booth. A shielded wire ran outside to a Terman amplifier that had a gain of 40dB. A gain control on the Terman was used to compensate for a loss of approximately 0.3dB from the cathode follower. The signal then went to a Daven precision attenuator and then to the chart recorder. A Ballantine voltmeter with a linear dB scale was used to monitor the voltage driving the AR-1.

A Western Electric 640AA condenser microphone was used to calibrate this test position. A response curve of the AR-1 was made using the WE 640AA. A correction for the WE 640AA response was made to the AR-1 curve using a calibration supplied with the microphone. The WE 640AA was periodically sent to the Bureau of Standards for calibration. By making a response curve at the test position for a microphone under test, it could be compared to the corrected AR-1 response. By subtracting one curve from the other, the resulting curve was the response of the microphone being tested. The curve subtraction was done by hand.

Hearing aid research had several pieces of Bruel & Kjaer test equipment and a special portable test enclosure for making measurements. The line voltage in the entire lab was regulated using a pair General Radio voltage regulators. Support was provided by a materials and chemistry lab, electronic maintenance section, and an extensive model shop. Experimental dies and plastic molded parts could be made easily in this shop.

![]()

Sound Level Meter Microphone

Sonotone 13979 Microphone

By 1972, Sonotone was owned by Gould and the facilities had moved in the left (south) wing of the original Sonotone building. For a short time, a sound level meter microphone was made. This was a smaller version of the CM-10A with a smaller diameter head. The connector was a 3-pin XLR type compatible with sound level measuring equipment.

Literature

The Sonotone sound level meter microphone is a reliable ceramic unit with a self-contained wind-screen which enhances its outdoor usefulness. The built-in wind-screen feature generates an equivalent 1.55 cc volume between the diaphragm and the top edge of the cap. This volume must be considered when closed coupler measurements are taken.

The metal case has a chrome finish and has the standard 0.936 diameter to fit ASA couplers. The integral three-pin connector mates with the standard Switchcraft #A3F connector or equivalent. The ceramic element has a nominal capacitance of 450 pf and may be connected floating or grounded at one end as required. This extremely rugged, stable microphone, suitable for field sound level measurements, has a free field, open circuit sensitivity 0f -59 dB re 1 volt per microbar.

![]()

During my stay at Sonotone, I got to know many of the people who worked there. Others I knew only briefly. Many of the names were of people in our research department and were distributed on a Christmas mailing list. There were lots of others in production and other departments that I was not acquainted with.

|

Paul Adler |

Wally Knopp |

|

Norman Dieter |

Ed Pietry |

![]()

Detailed List of Sonotone Microphones

SONO/COM Headset and Microphone Combination

Headsets were available in suntan, coral, spruce green and black. Ear cushions were attached with Velcro and were replaceable.

SHM-1000 Crystal headphone and ceramic noise canceling microphone. Response headset 80-10kHz, microphone50-10kHz. Sensitivity microphone -53dB. Weight 13 ounces

SHM-1100 Crystal headphone and magnetic noise canceling microphone. Response headset 80-10kHz, microphone100-10kHz. Sensitivity microphone -58dB. Impedance microphone 600 ohms. Weight 13-1/2 ounces.

SHM-1200 Low impedance ceramic headphone and ceramic noise canceling microphone. Response headset 80-10kHz, microphone50-10kHz. Sensitivity microphone -53dB. Weight 13 ounces

SHM-1300 Low impedance ceramic headphone and magnetic noise canceling microphone. Response headset 80-10kHz, microphone100-10kHz. Sensitivity microphone -58dB. Impedance microphone 600 ohms. Weight 13-1/2 ounces.

SH-2000 Crystal headset only. Response 80-10kHz. Weight 9-1/2 ounces.

SH-2100 Low impedance ceramic headset only. Response 80-10kHz. Weight 9-1/2 ounces.

SB-3000 Ceramic noise canceling boom microphone only. Response 50-10kHz. Sensitivity -53dB. Weight 3-1/2 ounces.

SB-3100 Magnetic noise canceling boom microphone only. Response 100-10kHz. Sensitivity -58dB. Weight 4 ounces.

![]()

CM-10A Ceramike. Response 50-11kHz. Sensitivity -56 dB within 2 dB. Seven foot shielded cable with phone plug. Price $18.40

CMC-10A Package of CM-10A microphone and CMS-10 desk stand. Price $23.00

CMT-10A Matched pair of CM-10A microphones for stereo recording. Price $37.30

CM-10A-39 Same specs as CM-10A. Ruggedized for hard usage applications. Price $19.45

CM-11A Ceramike. Response 50-11kHz. Sensitivity -53dB. Seven foot shielded cable with phone plug

CMC-11A Package of CM-11A microphone and CMS-10 stand. Price $23.00

CMT-11A Matched pair of CM-11A microphones for stereo recording. Price $37.30

CM-12A Ceramike. Response 200-8kHz. Sensitivity -63.5 dB within 2 dB. Seven foot shielded cable with phone plug. For PA systems in long lead installations. Low impedance with push-to-talk button.

CM-17A Ceramike. Response 50-11kHz. Sensitivity -56 dB within 2 dB. Six foot shielded cable. Mounted on 13" flexible gooseneck . For use in learning labs. Price $25.75

CM-17B Ceramike. Same as CM-17A but with 13" fixed boom mount with 350 degree swivel. six foot shielded cable. Price $29.95

CM-17C Ceramike. Same as CM-17A but with 6" flexible gooseneck. Seven foot shielded cable.

CM-17D Ceramike. Same as CM-17A but with 6" solid boom with fixed base mount. Seven foot shielded cable.

CM-17E Ceramike. Same as CM-17A but with 3" solid boom with fixed base mount. Seven foot shielded cable.

CM-17F Ceramike. Same as CM-17A but with 6" solid boom with 350 degree mount. Seven foot shielded cable.

CM-18 Ceramike. Mounted on 13" flexible gooseneck. Response 200-8kHz. Sensitivity -63dB within 2 dB. t with 13" fixed boom mount with 350 degree swivel. Seven foot shielded cable. Low impedance. For transistor applications

CM-18A Same as CM-18 but with push-to-talk button.

CM-30 Ceramike. Response 60-7kHz, Sensitivity -49dB within 2dB. Shatterproof plastic case. For mobile use. Push-to-talk button. Dashboard mounting bracket. Spring-spiraled 4-conductor shielded cable. Price $14.70

CM-30M Same as CM-30 but with dashboard magnet mount. Price $17.35

CM-3050 Ceramike. Response 170-7kHz, Sensitivity -62dB. Recommended impedance 33k. Shatterproof plastic case. Low impedance CB mike Push-to-talk button. Dashboard mounting bracket. Spring-spiraled 4-conductor shielded cable. Price $15.75

CM-3050M Same as CM-3050 but with dashboard magnet mount. Price $18.40

CM-40 Ceramike. Response 40-8kHz. Sensitivity -56dB. Low priced mike. Swing type stand. Price $10.40

CMS-10 stand. Has 5/8 No.27 thread for floor stand mounting

CM-1018 Ceramike. Response 50-10kHz. Sensitivity -56dB. Recommended impedance 500k. Low impedance mica for taping and communications.

CM-1050WR Ceramike. Response 30-10kHz. Sensitivity -58dB. Recommended impedance 250k. Low impedance mica for voice and music. With 7 feet of shielded cable without plug. Price $19.45

CMT-1050WR Matched pair of CM-1050WR within 2dB. Price $39.30

CMC-1050WR Combination CM-1050WR microphone and CMS-10 stand. Price $25.20

CM-1050SR Ceramike. Response 170-9.5kHz. Sensitivity -62dB. Recommended impedance 33k. Speech range low impedance microphone. With 7 feet of shielded cable and phone plug. Price $19.45

![]()

DM10-100 Response 80-16kHz. Sensitivity -57dB. Impedance 50k. With 7 foot shielded cable and phone plug. Price $24.50

DM10-200 Response 80-16kHz. Sensitivity -63dB. Impedance 10k. With 7 foot shielded cable and phone plug. Price $24.50

DM10-300 Response 80-16kHz. Sensitivity -77dB. Impedance 600 ohms. With 7 foot shielded cable and phone plug. Price $24.50

DM10-500 Response 80-16kHz. Sensitivity -80dB. Impedance 200 ohms. With 15 feet of two conductor shielded cable without plug. Price $24.50

DM10-550 Same as DM10-500 but with on-off switch. Price $25.50

DM17A-500 Response 60-16kHz. Sensitivity -78 dB. Six foot shielded cable without plug. Mounted on 13" flexible gooseneck . For use in learning labs. Price $34.50

DM17B-500 Same as DM-17A-500 but with 13" fixed boom mount with 350 degree swivel. Six foot shielded cable without plug. Price $38.50

DM70-100 Response 50-15kHz. Sensitivity -60dB. Impedance 50k. With 7 foot shielded cable and phone plug. Price $29.50

DM70-150 Response 50-15kHz. Sensitivity -58dB. Impedance 50k. With 7 foot shielded cable and phone plug. Price $29.50

DM70-200 Response 50-15kHz. Sensitivity -66dB. Impedance 10k. With 7 foot shielded cable and phone plug. Price $29.50

DM70-500 Response 50-15kHz. Sensitivity -83dB. Impedance 200 ohms. With 15 feet of two conductor shielded cable without plug. Price $29.50

DM70-550 Same as DM70-500 but with on-off switch. Price $29.50

CDM80 Cardioid pattern Response 80-12kHz. Dual impedance. Sensitivity -59dB and -81dB. Impedance 50k and 200 ohms. Front-to-back rejection 16-20dB over the entire range. With 15 foot 3 conductor shielded cable without plug. With on-off switch. Price $43.50

DM70-100-B Omni. Ball microphone. Response 50-15kHz. Sensitivity -58dB. Impedance 50k. Acoustical ball controls wind noises. With 7 foot shielded cable and phone plug. Price $39.00

DM70-150-B Same as DM70-100-B but with on-off switch. $42.50

DM70-200-B Omni. Ball microphone. Response 50-16kHz. Sensitivity -66dB. Impedance 10k. Acoustical ball controls wind noises. With 7 foot shielded cable and phone plug. Price $42.50

DM70-250-B Same as DM70-200-B but with on-off switch. $42.50

DM70-500-B Omni. Ball microphone. Response 50-18kHz. Sensitivity -89dB. Impedance 10k. Acoustical ball controls wind noises. With 15 foot two conductor shielded cable without plug. Price $39.00

DM70-550-B Same as DM70-500-B but with on-off switch. $42.50

Studio 70-L Response 40-18kHz. Sensitivity -79dB. Impedance 200 ohms. Packaged in vinyl carrying case with table stand, lavaliere and cord clip. With 18 feet of shielded cable. Price $79.00

Studio 70-H Response 50-15kHz. Sensitivity -58dB. Impedance 50k. Packaged in vinyl carrying case with table stand, lavaliere and cord clip. With 18 feet of shielded cable. Price $79.00

![]()

AD-10 Floor stand adapter. Clear plastic holder. Standard 5/8" No. 27 thread. Moves 180 degrees vertically. Price $4.50

CMS-10 Desk stand. Cast metal base. Clear plastic holder. Has 5/8 No.27 thread for floor stand mounting. Price $6.00

CMS1-10 Desk stand. Same as CMS-10 stand but with unbreakable white plastic holder. Price $6.40

LA-20 Black plastic lavaliere with adjustable neck strap. For all CM and DM microphones. Price $3.25

WS-10 Wind screen ball. Fits all CM-10 and DM-10 series microphones. Price $4.95

WS-70 Wind screen ball. Fits all DM-70 series microphones, except ball type. Price $4.95

13565 Dress grille for CDM80 series microphones. Price $.95

11735-1 Dress grille for DM10 series microphones. Price $.95

11735-2 Dress grille for CM-10 series microphones. Price $.95

11738-1 replacement clear plastic holder for CMS-10 stand. Price $2.65

11738-3 replacement white plastic holder for CMS1-10 stand. Price $2.65

34489 Dress grille for DM-10 series microphones. Price $.95

![]()

|

About This Site |

||

|

|

More text and pictures about Sonotone will be added as my research continues. Any comments, corrections, or additions are welcome. |

|

|

|

|

All contents

are copyrighted |